Thin-film composite polyamide membranes are the basis for modern commercial reverse osmosis (RO) membranes. These membranes are created through interfacial polymerization (IP) involving a trifunctional acid chloride (e.g., trimesoyl chloride, TMC, dissolved in an organic solvent) and a difunctional amine (e.g., m-phenylenediamine, MPD, dissolved in water). While these membranes excel in water permeability and salt rejection, their high surface roughness and uneven distribution of polar groups contribute to scaling/fouling of the membrane and make structure-property relationships difficult to achieve.

GW Researches, along with researchers at National Institute of Standards & Technology (NIST), have developed a novel rinse-free molecular layer-by-layer (mLbL) deposition technique that enables the fabrication of polyamide-based reverse osmosis membranes with low surface roughness and tunable membrane thickness and chemistry. The polymer deposition on the surface is controlled effectively by decreasing the solution concentration and volume, minimizing the presence of unreacted monomer after each cycle. These polyamide-based membranes display water flux and salt rejection comparable to a commercial brackish water membrane but with greatly enhanced tolerance to fouling. Our research highlights the potential for tailoring the mLbL process towards large scale manufacturing of RO membranes with low surface roughness, high resistance to fouling, and extended lifespan.

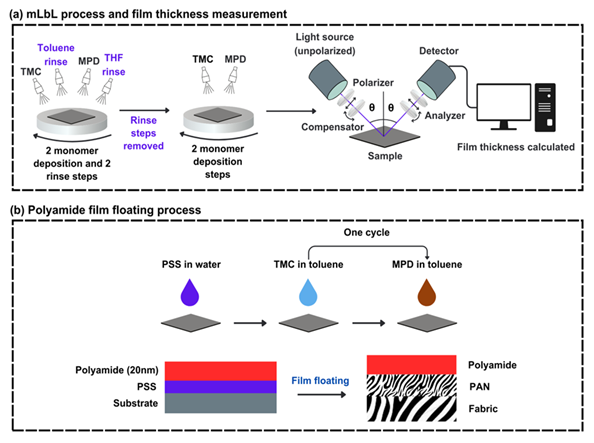

Figure. Schematic representation of the modified layer-by-layer (mLbL) process and film thickness measurement.

Advantages:

- Membranes have higher cross-link density and less free volume.

- Higher salt rejection.

- Exceptional resistance to fouling and mineral scaling

Applications:

- Large scale manufacturing of industrial-grade membranes.

- Water Filtration process.

- Desalination

- Household water purification systems